Texas Instruments to Demonstrate Ultrasonic Lens Cleaning Technology at CES

Texas Instruments will soon demonstrate the company's advanced ultrasonic lens cleaning technology at CES.

Ultrasonic lens cleaning is to clean the glass surface through precisely controlled high-frequency vibration. Especially on rainy days, this technology can automatically detect and remove raindrops from the lens of the car's rear camera without any action from the driver.

How does ultrasonic lens cleaning technology work?

Let's start with basic physics. All objects have a fixed frequency of oscillation, determined by their molecular structure and geometry. For example, guitar strings vibrate at their natural frequency when strummed. Likewise, a wine glass vibrates at its natural frequency when struck. If you repeatedly apply energy to a material at a specific natural frequency, the incoming wave will superimpose the existing waves—making them more intense but still in the same phase, a phenomenon called resonance.

To better understand resonance, imagine you're pushing someone on a swing. When at the top, pushing the swing at the right moment will swing you higher, conversely, if you push at the wrong moment, it will absorb some of the mechanical energy and reduce the swing height.

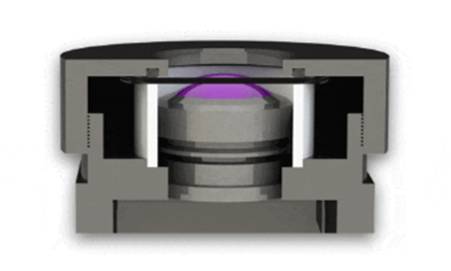

Glass, silicon, and polycarbonate lenses all have natural frequencies that depend on their shape and thickness. Applying ultrasonic vibrations (or vibrations outside the range of human hearing) at the natural frequencies of these materials causes them to resonate. Just as squealing at the natural frequency of a glass object causes it to resonate until it shatters, precise application of ultrasonic vibrations in special patterns using piezoelectric transducers and advanced semiconductors can effectively remove water, dirt and other contaminants from surfaces. Figure 1 below shows a cross-section of an ultrasonic lens cleaning system. Figure 2 then shows an animation of the drainage of the ultrasonic lens cleaning system. While the ultrasonic lens cap typically vibrates with a displacement of about 10 microns, which is less than the human eye can perceive, the animation is exaggerated for demonstration purposes.

Figure 1: Ultrasonic Lens Cleaning System

Figure 2: Animation of draining the ultrasonic lens cleaning system

Why is this technology important?

In 2014, the U.S. Department of Transportation made it mandatory for cars built after May 1, 2018 to have rear backup cameras. Today, some cars feature as many as eight cameras and other external sensors that use technologies such as lidar.

Those cameras and sensors are only useful if the footage is clear and unobstructed; splashes of mud or rain can easily disable some autonomous ADAS features. So, as cars become smarter, safer and more advanced, new requirements may emerge for these sensors to operate features such as automatic emergency braking in all weather conditions.

While ultrasonic cleaning already exists in fields such as medical, innovations in mechanical design, software algorithms, and semiconductor integration have enabled ultrasonic surface cleaning in open air. Self-cleaning camera lens technology isn't limited to the automotive industry either; virtually any application with a camera can take advantage of the technology, including traffic surveillance cameras, endoscopes, and machine vision cameras.

other cleaning methods

Automotive OEMs have experimented with camera cleaning methods such as miniaturized windshield wipers, compressed air and rotating lenses. Unfortunately, these methods are complex, expensive, and not suitable for all situations. Some high-end vehicles are equipped with hidden sprinklers to wash camera lenses, a method that requires additional plumbing and fluids, and water sprays won't remove ice, as well as rain.

Ultrasonic lens cleaning systems use mechanical vibrations to quickly generate heat that melts ice and blasts away water. They can continuously remove rainwater from the lenses by automatically sensing water and misting it through vibration. With the right algorithms and mechanical design, these systems can remove other contaminants such as dust, mud and even insects. It might sound complicated, but specialized semiconductors can do it in a very small footprint. Using dedicated semiconductors, automated ultrasonic lens cleaning systems can be self-contained, relying only on power and an optional data cable.

in conclusion

For safe and reliable cars, I expect the automotive industry to adopt ultrasonic cleaning of lenses; other types of end equipment, such as agricultural automation systems, traffic cameras, and sports filming, may also adopt this technology because of the performance advantages, operational efficiency and Simplified maintenance.

At CES, we'll see how this ultrasonic cleaning technology can help make lenses cleaner and safer.